Toyota Leads the Way with SAS

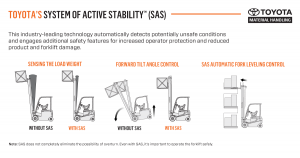

Toyota has built its reputation on the quality and safety of their products. This commitment to quality and safety extends even to used Toyota forklifts and the rigorous tests used forklifts must go through in order to become Toyota Certified Reconditioned Forklifts. Not content to rest on their laurels, Toyota continues to explore ways to improve their lift trucks. One of the latest improvements in Toyota lift truck technology is their System of Active Stability (SAS).

What is SAS?

The reason why SAS is called an active stability system is because it literally becomes active when the forklift is in operation. SAS does this in six different ways:

1 Through its swing lock cylinder.

2. Via a tilt angle control mast front mechanism and a

3. Mast rear tilt speed control.

4. Through its active steering synchronizer,

5. A 1 touch fork leveling control and

6. Automatic speed reduction when cornering (on 3-wheel counterbalance Toyota forklifts).

Image courtesy of Toyota Forklift – Bahrns ToyotaLift is an award-winning Toyota Forklift Dealership

Together, these innovative features give the forklift much greater lateral (sideways), longitudinal (forward and backwards) and yaw (tilt) stability. This active stability system is in contrast to older forklifts that all rely on a simple passive system based on the stability triangle. The only problem with operating most forklifts is that forklift operators are too often tempted to push their lift trucks to their limits or don’t know what those limits are. All it takes is one simple error to push a forklift beyond its limits and a serious or fatal accident occurs.

While SAS sounds great in theory, does it really work? Toyota wanted to know the answer to that question, too, so they put their system to the test. It wasn’t easy, because no current standards exist to determine lateral overturn risk exposure. However, France’s Institut National de Recherché et de Sécurité (INRS) and Germany’s University of Hamburg jointly conducted research that gave Toyota a dynamic lateral stability protocol to work with. French testing agency UTAC used this protocol to test the stability of Toyota forklifts with SAS versus standard forklifts and they passed with flying colors. After 200 tests conducted by highly experienced forklift operators, the Toyota Tonero was the only forklift whose inner wheel did not leave the ground when turning sharply.

Unfortunately, it will probably be a few years before SAS equipped Toyota forklifts enter the used forklift market. Until then, and even after you can find them in the reconditioned forklift market, there’s no substitute for forklift safety training and a thorough understanding of forklift stability. For some basic information about forklift stability, read Forklift Stability Basics and for an overview of forklift carrying capacities, check out Determining Your Forklift Carrying Capacity. For more in-depth information, we recommend the forklift training materials available on the OSHA website and on our other website, Forklift Accessories. While you’re visiting forkliftaccessories.com, be sure to also have a look around the site and find forklift attachments and accessories that can help you get the most out of your used forklift.

Check out this video for more information about Toyota’s remarkable System of Active Stability and see why Toyota leads the way with SAS and other advanced forklift technologies.